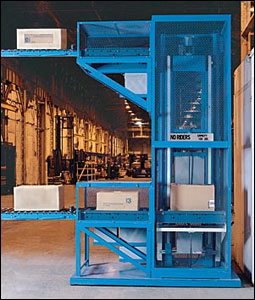

ACG Conveyors’, “Fully Automated Vertical Reciprocating Conveyor” is custom designed to fit your exact application needs. These systems range from simple two-level applications to sophisticated multi-level, multi-directional systems. Our automated systems can provide both vertical and horizontal conveyor means. Many options are available, such as: mode reversal, queuing of loads, full-queue signals, warning signals, door operators, condition lights, load stops, self-diagnostics.

ACG Conveyors offer single source responsibility for system design, installation, start-up, training and debugging by factory trained technicians.

VRC Features:

- PLC based controls

- 15,000 lbs. Load capacity

- Standard 10’x12′ carriage

- Flexible loading/unloading

- Wide range of configurations

- Hazardous or corrosive environments

ACG Conveyors offer VRCs that range from mechanical to hydraulic to fully automatic, customized systems for automated manufacturing and warehousing operations. VRCs are available in capacities from 10 lbs. to 130,000 lbs. with carriages from 30 x 30 in. to 30 x 60 ft., vertical heights to over 200 ft. and travel speeds to 400 fpm.

![]() NEW in 2018! PFLOWs Most Current Brochure

NEW in 2018! PFLOWs Most Current Brochure

![]() PFlow VRC Lift Brochure

PFlow VRC Lift Brochure

American Conveyor Group (ACG Conveyors) and PFlow Industries Inc., provides total engineering, fabrication and installation services and guarantees code approval in every state.

.

Vertical Reciprocating Conveyor Application Guidelines

Vertical Reciprocating Conveyors (VRC) moves materials in factories, warehouses, industrial plants, institutions or anywhere that products or supplies need to move from one level to another. VRCs are not elevators. In fact, they have their own national code (ANSI/ASME B20.1) and are specifically exempt from the national elevator code. VRCs provide fast, efficient, convenient and safe access to/from mezzanines, balconies, basements, and between levels in multiple story buildings. They can be installed for through-floor, interior or exterior applications. The principal components of a VRC include guide columns, carriage and a mechanical or hydraulic actuating mechanism.

Vertical Reciprocating Conveyor Application Guidelines.

- Safely transport materials from one level to another

- Install in new or existing building

- Customized to your application needs

- Less costly to install, operate and maintain than elevators

- Safer than using a forklift to move materials between levels

- Move loads of all shapes, sizes and weights from 10lbs. to 130,000 lbs.

- Designed for mezzanines, through-floor and other multi-level applications

- Install in unused elevator shafts

- Proven in over 10,000 applications

- Safe, efficient, convenient means of moving materials vertically

- Meet or exceed ANSI B20.1 and OSHA regulations

- Hydraulic, mechanical and fully automated systems

- Equipped with advanced safety features to protect men and materials

- Turnkey installation available

![]() Download Application Guidelines.

Download Application Guidelines.