PFlow | Hydraulic Vertical Conveyors

We have three series of PFlow’s Hydraulic Vertical Conveyors:

- Hydraulic Vertical Conveyors, Series 21,

- Hydraulic Vertical Conveyors, Series D Lift, and

- Hydraulic Vertical Conveyors, Lift Series DM

- NEW in 2018! PFLOWs Most Current Brochure

1. Hydraulic Vertical Conveyors, “Series 21”

- Hydraulically lift loads up to 6,000 lbs

- Carriage sizes to 10 ft. x 10 ft.

- Vertical rise height up to 22 feet.

- To assure long term operation, our guide columns are heavier than other vertical lifts conveyors on the market and have oversized bearings for a life expectancy of over 20 years.

- For Specifications on the PFlow Hydraulic Vertical Reciprocating Conveyor “Series 21”. Click “Series 21 Specifications” below.

Series 21 Two Page Brochure

Series 21 Two Page Brochure Series 21 Owner’s Manual (No DeckLocks) Installation Manual

Series 21 Owner’s Manual (No DeckLocks) Installation Manual

Hydraulic Vertical Conveyors, Series 21

- Heavy torsion bar links the two hydraulic lift cylinders to equalize the load, eliminate twisting of the carriage and relieve stress on the guides, columns and carriage.

- Dual, spring-loaded safety cams provide added protection against uncontrolled descent.

- Hydraulic lift mechanism uses heavy-duty roller chain instead of cable for added quality, strength and durability – up to 10 times longer life.

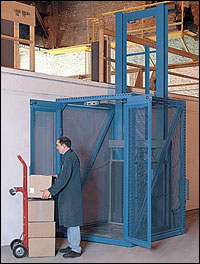

- Other safety features include 8 ft. high mesh enclosures, safety gates at each level, safety chains and railings, overtravel protection, backstop panels and remote, heavy-duty control stations. All gates are electrically and mechanically interlocked with carriage movement and lift operation.

- Hydraulic Vertical Conveyors provide reliable, economical vertical lifting for mezzanines, balconies and other two-level applications. ACG can provide you with a heavy-duty hydraulic VRC with advanced safety technology and proven reliability. These lifts are available with straddle or cantilever carriages.

- Hydraulically lifts loads to 6,000 lbs with carriage sizes to 10 ft. x 10 ft. vertical rise to 22 ft., travel speeds from 25 fpm to 35 fpm.

- Features guide columns that are heavier than other vertical lifts on the market and oversized bearings with a life expectancy of over 20 years – to assure long term operation.

Hydraulic Vertical Conveyors, Series 21 Specifications

General:

Pflow Series 21 Hydraulic Vertical Conveyor (i.e., Hydraulic Vertical Lifts) move materials between two levels. Principal components are guide columns, carriage and hydraulic actuating mechanism.

Application Data:

Pflow Series 21 Hydraulic Vertical Conveyor and Vertical Lifts are available with: Lifting capacities to 6,000 lbs.; carriage sizes to 10′ x 10′; vertical rise to 22′. Standard travel speed is 24 fpm. Speeds to 35 fpm are available on special order.

Structure:

Guide columns are 6″ wide flange. Carriage is fabricated of 4″ or 6″ structural members with steel deck plate. Other deck surfaces can be supplied. Carriage is available in straddle or cantilever styles.

Operation:

Carriage is lifted and lowered by two hydraulic cylinders mounted on guide columns. Cylinders are actuated by a remote mounted hydraulic pump. Transmission of the lifting force is through roller chain attached to the cylinders and carriage. A torsion bar links the two cylinders to equalize the load and ensure carriage remains level at all times.

Electrical:

Standard power requirements are 208V/230V/460V, 3-phase. Single-phase is an available option. Control voltage is 24V. Control stations and remote mounted control panel are NEMA 12. Control stations, provided for each level, include self-maintaining push buttons with mushroom-head E-Stop button.

Safety Features:

Overtravel is prevented by positive mechanical stops. Safety cams prevent uncontrolled descent in case both chains break. Velocity fuses prevent uncontrolled descent in case of hydraulic hose rupture. NO RIDER signs are posted at each point of operation. Optional DeckLocks automatically lock carriage at the upper level to eliminate drift or bounce. Carriage will not move if loaded to more than 120% of rated capacity.

Carriage Side Guards:

Carriage is equipped with safety rails on non-operating sides and safety chains or diagonal drop bars on operating ends. Optional expanded metal or sheet metal carriage side guards are available.

Safety Enclosures:

Safety codes (ANSI/ASME B20.1) require gates and enclosures on all sides of the lift. Enclosures must be a minimum of 8′ high and reject a ball 2″ in diameter. Pflow manufactures gates and enclosures with 1/2″ expanded metal in a structural angle frame. Gates are accessible during loading/unloading and are electrically and mechanically interlocked with carriage movement. Interlocks prevent gates from being opened unless the carriage is at the designated level and also prevent carriage movement if any gates are not fully closed and locked.

2. Hydraulic Vertical Conveyors “Series D Lift”

- Two (2″) ram direct acting hydraulic cylinders

- Lifts loads up to 3,000 lbs.

- Carriage sizes large as 6ft. x 6ft.

- Vertical rise heights to 14 ft.

- For Specifications on the PFlow Hydraulic Vertical Conveyor “Series D Lift”. Click “Series D Lift Specifications” below.

Series D Two Page Brochure

Series D Two Page Brochure Series D Owner’s Manual Installation Manual

Series D Owner’s Manual Installation Manual

Hydraulic Vertical Conveyors, Series D Lift

- PFlow’s Hydraulic Vertical Conveyor provide reliable, economical vertical lifting for mezzanines, balconies and other two-level applications. ACG can provide you with a heavy-duty hydraulic VRC with advanced safety technology and proven reliability. These lifts are available with straddle or cantilever carriages.

- Guided Dual-Pak design has no cables, chains, bearings or other components that can break or require lubrication. It is ideal for mezzanine and balcony applications.

- The carriage is lifted and lowered by dual 2 in. ram direct acting hydraulic cylinders, and lifts loads up to 3,000 lbs. The carriage can be constructed as large as 6 ft. x 6 ft. It has a vertical rise to heights of 14 ft. and can travel at speeds from 17 fpm to 25 fpm.

- Pressure-compensated control valve regulates flow of hydraulic oil to assure smooth and constant speed under any load.

- Roll-formed columns provide precise carriage guidance, eliminate rocking and assure smooth ascent/descent.

- Ultra high molecular weight polyethylene cylinder guide prevents cylinders from twisting during operation and improves cylinder life.

- Hydraulic system is fully pressurized at the upper level to reduce drifting or bounce as the carriage is loaded/unloaded.

- Remote mounted control panel and TEFC motor are prewired and ready for immediate installation.

- Durable, high-quality construction ensures safe, reliable and long-term performance.

Hydraulic Vertical Conveyors, Series D Specifications

General:

Pflow Series D Hydraulic Vertical Conveyors, (i.e., Vertical Lifts) move materials between two levels. Principal components are guide columns, carriage and hydraulic actuating mechanism.

Application Data:

Pflow Series D Hydraulic Vertical Conveyors, and Vertical Lifts are available with: Lifting capacities to 3,000 lbs.; carriage sizes to 6′ x 6′; vertical rise to 14′. Standard travel speed is 17 fpm. Speeds to 25 fpm are available on special order.

Structure:

Guide columns are 6″ wide flange sections. Carriage is fabricated of 4″ or 6″ structural members with steel deck plate. Other deck surfaces can be supplied. Carriage is cantilever style and may be loaded from any one of three operating sides depending on application.

Operation:

Carriage is lifted and lowered by direct-acting hydraulic cylinders. Cylinders are actuated by a remote mounted hydraulic pump. Transmission of the lifting force is direct from the base of the columns to the carriage using a Dual-Pak ram.

Electrical:

Standard power requirements are 208V/230V/460V, 3-phase. Single-phase is an available option. Control voltage is 24V. Control stations and remote mounted control panel are NEMA 12. Control stations, provided for each level, include self-maintaining push buttons with mushroom-head E-Stop button. Quick-connect cabling is provided.

PFlow Hydraulic Vertical Conveyors Safety Features:

Upward travel of the carriage is limited by positive mechanical stops that ensure positive leveling with the upper deck. Redundant overload protection is provided to positively prevent raising of the carriage if loaded to more than 120% of rated capacity. Velocity fuses prevent uncontrolled descent in case of hydraulic hose rupture. NO RIDER signs are posted at each point of operation.

Carriage Side Guards:

Carriage is equipped with safety rails on non-operating sides and safety chains or diagonal drop bars on operating ends. Optional expanded metal or sheet metal carriage side guards are available.

Safety Enclosures:

Safety codes (ANSI/ASME B20.1) require gates and enclosures on all sides of the lift. Enclosures must be a minimum of 8′ high and reject a ball 2″ in diameter. Pflow manufactures gates and enclosures with 1/2″ expanded metal in a structural angle frame. Gates are accessible during loading/unloading and are electrically and mechanically interlocked with carriage movement. Interlocks prevent gates from being opened unless the carriage is at the designated level and also prevent carriage movement if any gates are not fully closed and locked.

3. Hydraulic Vertical Lift “Series DM”

- Two (2″) ram direct acting hydraulic cylinders

- Lifts loads up to 3,000 lbs.

- Carriage sizes large as 6ft. x 6ft.

- No cables, chains, bearings or other components that can break or require lubrication

. - For Specifications on the PFlow Hydraulic Vertical Reciprocating Conveyors “Series DM”. Click “Series DM Specifications” below.

Hydraulic Vertical Conveyors / Vertical Lift Series DM

The Series DM is a modular version of the Series D Hydraulic Vertical Conveyor Lift, and is delivered in two or three, stackable, bolt-together sections for one-day installation. The new modular lift provides low-maintenance, efficient material lifting of loads up to 3,000 lbs between two levels, and is especially suited for mezzanine or balcony applications in both new construction and existing structures.

The Series DM lift is driven by dual 2″ ram direct-acting hydraulic cylinders, and has no cables, chains, bearings or other components that can break or require lubrication. Available with either a 5 ft x 5 ft or 6 ft x 6 ft carriage, and in either 2,000 lbs and 3,000 lbs capacity models, the new lift easily moves loads to heights of 15 ft at a speed of 17 feet per minute. The unit is fully self-supporting and, depending on the application, can be loaded and unloaded from any of three operating sides on both levels. Unlike comparable competitor models, the Pflow Modular Series D uses no chains or cables, requires no safety cams, requires no expensive drop tests and requires far less maintenance and parts replacement. The new modular lift also fully meets ASME B20.1 code.