PFlow | Mechanical Vertical Conveyor Lift

PFlow | Mechanical Vertical Conveyor Lift

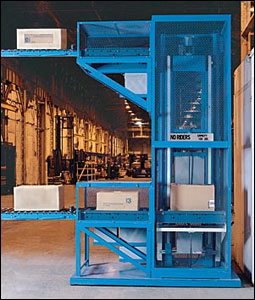

A versatile and dependable Mechanical Vertical Conveyor for high-speed, multi-level applications for large or heavy loads. Our Mechanical Vertical Conveyors are heavy-duty and offer maximum flexibility.

American Conveyor Group offers PFlow Mechanical Vertical Conveyor Lifts in four series:

- Series DB,

- Series F,

- Series M, and

- Series B.

- NEW in 2018! PFLOWs Most Current Brochure

1. “Series DB” Mechanical Vertical Conveyor Lift

- NEW! Available with high-speed variable frequency or Servo drive packages.

- Mechanical Vertical Conveyor Lift, Series DB lifts provides fast, safe vertical lifting of small loads and packages

- Ideal for high-speed applications that require light-duty lifting of boxes, cartons, packages, etc.

- Requires minimal maintenance — lifting belt never needs lubricating

- Versatile, completely self-contained, and economical.

- Lifts up to 100 lb. live loads with carriage sizes up to

- 3 ft. x 4 ft. Vertical rise to 50 ft.

- Standard travel speed of 60 FPM (Up to 400 FPM)

- Allows loading and unloading from three sides

2. “Series F” Medium-Capacity Mechanical Vertical Conveyor Lift

- Ideal for high speed, high cycle or automated systems.

- Conforms to ASME B20.1 Safety Standards.

- Mechanical Vertical Conveyor Lift Series F Lifts offers maximum capacity, for the heaviest lifting applications.

- Lifts heavy, bulky, oversized loads up to 50,000 lbs.

- Transports multiple pallet loads, or heavy machinery.

- Can be loaded/unloaded from all four sides.

- Unlimited carriage sizes.

- Unlimited vertical rise.

- Standard travel speed of 20 FPM (up to 400 fpm).

- Heavy-duty construction for reliability and long-term.

- Available with patented DeckLock system which automatically locks the carriage at critical upper levels and eliminates carriage bounce or drift.

- Can be used indoor or outdoor.

3. “Series M” Heavy-Duty Mechanical Vertical Conveyor Lift

A PFlow Series M Mechanical Vertical Lift is the most versatile Vertical Reciprocating Conveyor.

- Mechanical Vertical Conveyor Lift Series M Lifts offers High Performance and Durability with a Proven 2-Post Mechanical Design

- Designed to transport large, heavy loads between two or more levels. Ideal for high-cycle, automated systems or frequent use applications.

- Lifts up to 8,000 lb. loads with carriage sizes up to 10 ft. x 12 ft. Vertical rise to 200 ft.

- Heavy-duty construction provides superior strength, reliability and long-term performance.

4. “Series B” Mechanical Vertical Conveyor Lift

- Mechanical Vertical Conveyor Lift Series B Lifts are ideal for lifting boxes, cartons, barrels, cases, individual parts or miscellaneous items.

- Completely self-contained, self-supporting and economical

- Durable, high quality construction ensures safe, reliable long-term performance.

- Capacity up tor 500 lbs. with 3′ x 3′ carriage.

- Carriage decelerates which extends brake life.

- Allows loading and unloading from three sides.

- Unlike similar lifts in the industry, Series B Lift is ASME B20.1 Code compliant.