SmartPace Dynamic Pacing Conveyor

Dorner’s SmartPace Dynamic Pacing Conveyor is a pacing conveyor that takes randomly spaced items and places them evenly spaced. It is a completely non-contact system that doesn’t use guides, plows or diverts. SmartPace uses HMI interface to control the spacing, speed and orientation of products. It is capable of creating evenly spaced products or alternating groups of products. It can also merge multiple lines without product stops or gates. The entire process is very smooth and seamless.

How the SmartPace Conveyor Works:

- Randomly spaced product enter the conveyor

- A photoeye detects product spacing and,

- A servo motor automatically varies the conveyor speed and placement to create an evenly spaced products

SmartPace Performance Specs

Up to 200 feet per min belt speed

Up to 200 feet per min belt speed- Can smoothly transfer products as short as 3 inxhes in length

- Multiple approved FDA belt options

- Maintenance free, self-tracking, conveyor belts

- Available in aluminum or stainless steel frame

SmartPace Conveyor Specifications

4 inches to 12 inches wide and 6 feet long

4 inches to 12 inches wide and 6 feet long- 1.25 inch diameter transfer rollers

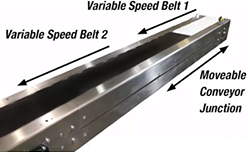

- Movable conveyor junction driven by plastic/stainless chain

- Two (2) independent (self tracking) belted conveyors

- Motors are mountable on either side or on both sides of conveyor

- All conveyor bearings are sealed for life

Servo Gear Motors

- Three (3) Servo gear motors drive the conveyor and transfer location

- Two (2) Conveyor drive motors (Yaskawa SGMGV-05) Servo Motors

- One (1) Junction drive motor (Yaskawa SGMGV-13) with right angle gear reducer

Controls

- A Yaskawa MP3200iec Motion Controller

- 230 V, 1 Phase Input (also available, 3 Phase, 230 V and 460 V, 50/60 Hz)

- Stand alone control with HMI interface

- Programmable product patterns and/or spacing

- Built-in safety control circuitry

- Available, remote enable and run signals

- Also available, system ready and fault outputs

Dorner SmartPace Conveyors

To enlarge video, Click the lower right ![]() icon.

icon.